UL 4703 PV 600V Tin-plated Copper Core Solar Photovoltaic Cable

UL 4703 Photovoltaic Wire is a UL certified wire and cable suitable for internal and external circuit connections of photovoltaic power generation system equipment. It can meet extreme climate conditions and long-term installation and use requirements, and can be widely used in photovoltaic systems of solar power plants and other fields.

This wire adopts high-quality copper conductor and special PVDF covering material, which has high electrical conductivity and excellent weather resistance. It has a rated temperature of 90°C and a rated voltage of 600V, which can withstand higher current loads and has better flame retardancy.

The size standard of this product complies with international standards such as the Institute of Electrical Engineers (IEEE) and the Canadian Society of Engineers (CSA). Its special structural design makes it highly wear-resistant, flexible and strong, not easy to break and damage.

UL 4703 photovoltaic wires are widely used in photovoltaic power generation systems and are efficient, reliable and safe wires and cables. It can help photovoltaic systems achieve efficient energy conversion and distribution, ensure the smooth operation of photovoltaic power generation systems, reduce energy costs, and improve power generation efficiency.

In conclusion, UL 4703 photovoltaic wire is a high-quality wire and cable product with stable performance, safety and reliability, which has important application value and market prospect. If you need safe and reliable photovoltaic wires, UL 4703 wires are your wise choice.

Technical data:

| Nominal voltage | 600V AC |

| Voltage test on completed cable | 3.0kv AC, 1min |

| Ambient temperature | (-40°C up to +90°C) |

| Max.Temperature at conductor | +120°C |

| The expected period of use is 25years Ambiet temperature | (-40°C up to +90°C) |

| The permitted short-circuit-temperature refer to a period of 5s is+200°C | 200°C, 5 seconds |

| Bending radius |

≥4xϕ (D<8mm) |

| ≥6xϕ (D≥8mm) | |

| Relative permittivity | UL854 |

| Cold bending test | UL854 |

| Weathering/UV-resistance | UL2556 |

| Fire test | UL1581 VW-1 |

| Heat distortion test | UL1581-560(121±2°C)x1h, 2000g, ≤50% |

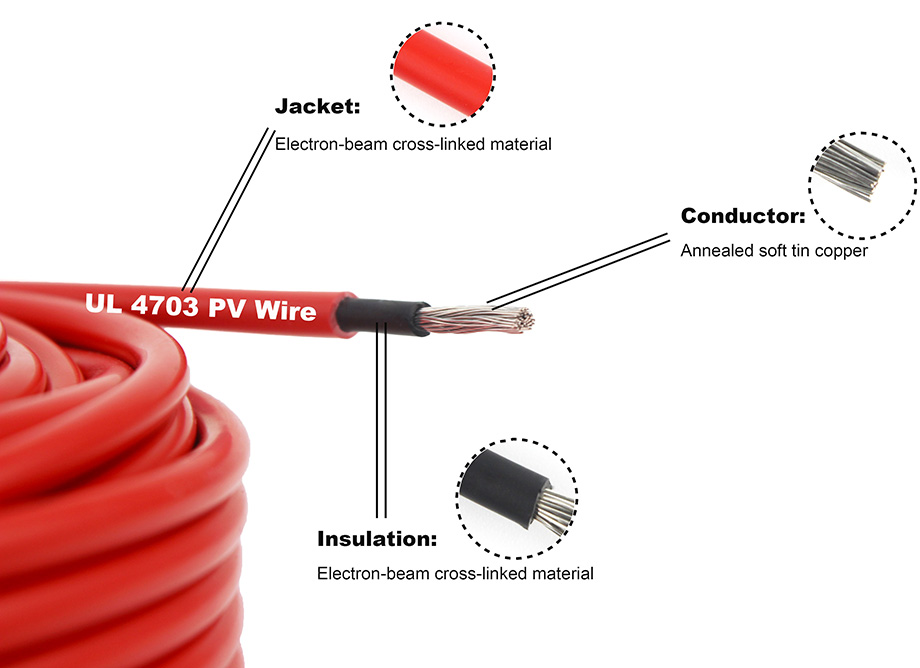

The Structure of Cable UL4703:

| Cross section(AWG) | Conductor Construction(no/mm) | Conductor Stranded OD.max(mm) | Cable OD.(mm) | Max Cond Resistance(Ω/km,20°C) | Current carring Capacity AT 60°C(A) |

| 18 | 16/0.254 | 1.18 | 4.25 | 23.20 | 6 |

| 16 | 26/0.254 | 1.49 | 4.55 | 14.60 | 6 |

| 14 | 41/0.254 | 1.88 | 4.95 | 8.96 | 6 |

| 12 | 65/0.254 | 2.36 | 5.40 | 5.64 | 6 |

| 10 | 105/0.254 | 3.00 | 6.20 | 3.546 | 7.5 |

| 8 | 168/0.254 | 4.10 | 7.90 | 2.23 | 7.5 |

| 6 | 266/0.254 | 5.20 | 9.80 | 1.403 | 7.5 |

| 4 | 420/0.254 | 6.50 | 11.50 | 0.882 | 7.5 |

| 2 | 665/0.254 | 8.25 | 13.30 | 0.5548 | 7.5 |

Application Scenario:

Global Exhibitions:

Company Profile:

DANYANG WINPOWER WIRE&CABLE MFG CO., LTD. currently covers an area of 17000m2, has 40000m2 of modern production plants, 25 production lines, specializing in the production of high-quality new energy cables, energy storage cables, solar cable, EV cable, UL hookup wires, CCC wires, irradiation cross-linked wires, and various customized wires and wire harness processing.

Packing & Delivery: