UL 4703 PV 1000V OR2000V Tin-plated Copper Core Solar Photovoltaic Cable

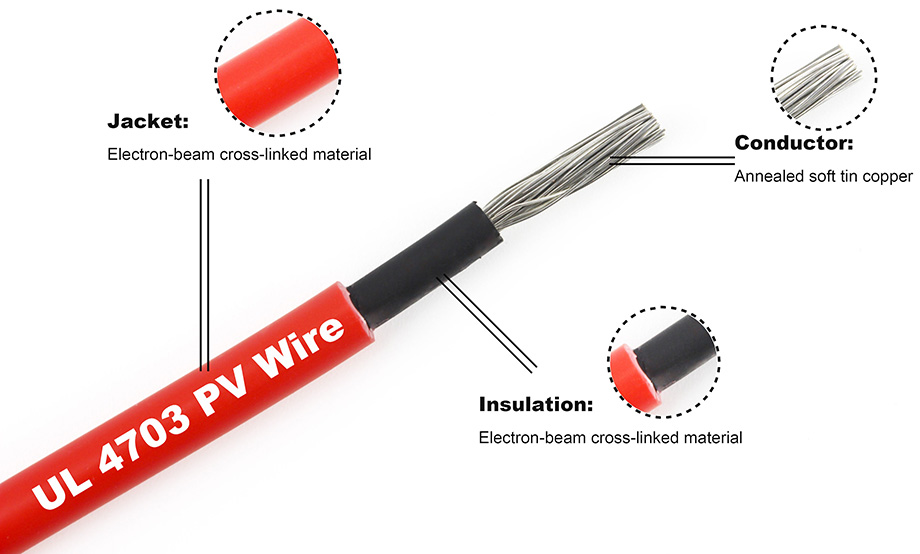

UL 4703 photovoltaic circuit cable sheath is made of cross-linked polyolefin insulation material, copper core is made of tinned pure copper, double-layer sheath design, wear-resistant, waterproof, oilproof, high temperature resistance, ozone resistance, can more effectively protect the cable, low resistance, low eccentricity, strong flexibility, long service life. Low power consumption, ideal for high-frequency applications. Photovoltaic cables are different from ordinary cables: photovoltaic cables are exposed to sunlight, and solar systems are often used under harsh environmental conditions, such as high temperatures and ultraviolet radiation. The cross-linked material has high mechanical strength, the cross-linking process changes the chemical structure of the polymer, the fusible thermoplastic material is converted to non-fusible elastomer material, and the cross-link radiation significantly improves the thermal, mechanical and chemical properties of the cable insulation material.

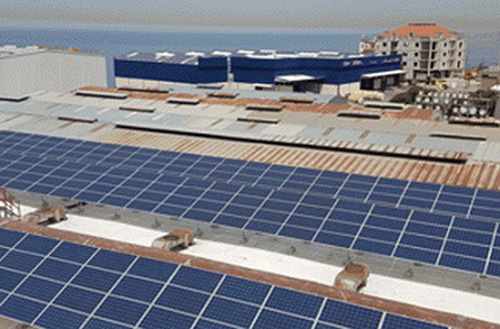

UL 4703 photovoltaic wire is UL product certified wire and cable, suitable for photovoltaic power generation system equipment internal and external circuit connection, can meet extreme weather conditions and long-term installation and use requirements, can be widely used in solar power plant photovoltaic system and other fields.

Technical data:

| Nominal voltage | 1000V AC OR 2000V AC |

| Voltage test on completed cable | 6.0kv AC, 1min |

| Ambient temperature | (-40°C up to +90°C) |

| Max.Temperature at conductor | +120°C |

| The expected period of use is 25years Ambiet temperature | (-40°C up to +90°C) |

| The permitted short-circuit-temperature refer to a period of 5s is+200°C | 200°C, 5 seconds |

| Bending radius |

≥4xϕ (D<8mm) |

| ≥6xϕ (D≥8mm) | |

| Relative permittivity | UL854 |

| Cold bending test | UL854 |

| Weathering/UV-resistance | UL2556 |

| Fire test | UL1581 VW-1 |

| Heat distortion test | UL1581-560(121±2°C)x1h, 2000g, ≤50% |

The Structure of Cable Refer to UK4703:

| Cross section(AWG) | Conductor Construction(no/mm) | Conductor Stranded OD.max(mm) | Cable OD.(mm) | Max Cond Resistance(Ω/km,20°C) | Current carring Capacity AT 60°C(A) |

| 18 | 16/0.254 | 1.18 | 5.00 | 23.20 | 6 |

| 16 | 26/0.254 | 1.49 | 5.30 | 14.60 | 6 |

| 14 | 41/0.254 | 1.88 | 5.70 | 8.96 | 6 |

| 12 | 65/0.254 | 2.36 | 6.20 | 5.64 | 6 |

| 10 | 105/0.254 | 3.00 | 6.90 | 3.546 | 7.5 |

| 8 | 168/0.254 | 4.10 | 8.40 | 2.23 | 7.5 |

| 6 | 266/0.254 | 5.20 | 10.30 | 1.403 | 7.5 |

| 4 | 420/0.254 | 6.50 | 11.70 | 0.882 | 7.5 |

| 2 | 665/0.254 | 8.25 | 13.50 | 0.5548 | 7.5 |

Application Scenario:

Global Exhibitions:

Company Profile:

DANYANG WINPOWER WIRE&CABLE MFG CO., LTD. currently covers an area of 17000m2, has 40000m2 of modern production plants, 25 production lines, specializing in the production of high-quality new energy cables, energy storage cables, solar cable, EV cable, UL hookup wires, CCC wires, irradiation cross-linked wires, and various customized wires and wire harness processing.

Packing & Delivery: