TUV PV1-F Double Parallel Photovoltaic Line Photovoltaic Line Solar Photovoltaic DC Line

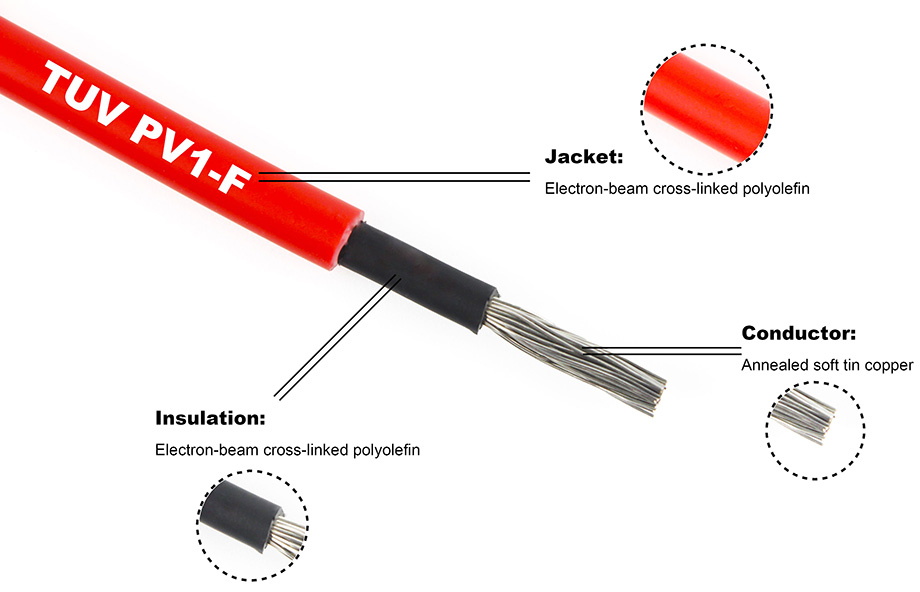

TUV PV1-F double parallel photovoltaic circuit copper core adopts surface tin plating process, with oxidation resistance, not easy to rust, good conductivity and other characteristics, the internal use of 99.99% pure copper, low resistance, can reduce the current conduction process of power consumption. The cable outer skin adopts insulation protective sleeve, double protective conductor, long service life, high temperature resistance, cold resistance, friction resistance, ozone resistance and ultraviolet radiation resistance, which can more effectively protect the cable and increase the service life.

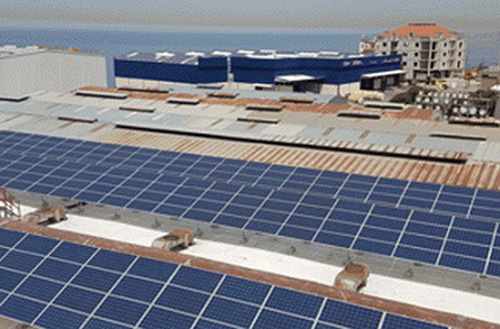

TUV PV1-F double parallel photovoltaic line has passed the TUV Rheinland product certification wire and cable, generally used in solar power plants and distributed rooftop photovoltaics, as well as construction, agriculture, fishery, public facilities, landscape construction, etc.

Technical data:

| Conductor | Tinned copper, according to VDE0295/IEC60228, class 5 |

| Outer sheath | Polyolefin copolymer electron-beam cross-linked |

| Rated voltage | AC Uo/U=1000/1000VAC, 1500VDC |

| Voltage test on finished cable | 6.5kV AC, 15kV DC, 5min |

| Ambiet temperature | (-40°C up to +90°C) |

| Conductor maximum temperature | +120°C |

| Service life | >25years(-40°C up to +90°C) |

| The permitted short-circuit-temperature refer to a period of 5s is+200°C | 200°C, 5 seconds |

| Bending radius |

≥4xϕ (D<8mm) |

| ≥6xϕ (D≥8mm) | |

| Acid and alkali resistance test | EN60811-2-1 |

| Cold bending test | EN60811-1-4 |

| Damp heat test | EN60068-2-78 |

| Sunlight resistance | EN60811-501, EN50289-4-17 |

| O-zone resistance test of finished cable | EN50396 |

| Fire test | EN60332-1-2 |

| Smoke density | IEC61034, EN50268-2 |

| Assessment of halogens for all non-metallic material | IEC670754-1 EN50267-2-1 |

The Structure of Cable Refer to EN50618:

| Insulation | Sheath | Cable outside diameter | ||||

| Core*Cross section(mm²) | Conductor Construction(no/mm) | Ave.Thic.(mm) | Ave.Thic.(mm) | minimum outer diameter(mm) | Max Cond Resistance(Ω/km,20°C) | Current carring Capacity AT 60°C(A) |

| 2*1.5 | 30/0.25 | 0.70 | 0.80 | 5.00*10.30 | 13.7 | 30 |

| 2*2.5 | 49/0.25 | 0.70 | 0.80 | 5.20*10.80 | 8.21 | 41 |

| 2*4.0 | 56/0.285 | 0.70 | 0.80 | 5.50*11.20 | 5.09 | 55 |

| 2*6.0 | 84/0.285 | 0.70 | 0.80 | 6.20*12.60 | 3.39 | 70 |

| 2*10 | 84/0.4 | 0.70 | 0.80 | 7.50*15.20 | 1.95 | 98 |

| 2*16 | 128/0.4 | 0.70 | 0.80 | 9.60*19.70 | 1.24 | 132 |

Application Scenario:

Global Exhibitions:

Company Profile:

DANYANG WINPOWER WIRE&CABLE MFG CO., LTD. currently covers an area of 17000m2, has 40000m2 of modern production plants, 25 production lines, specializing in the production of high-quality new energy cables, energy storage cables, solar cable, EV cable, UL hookup wires, CCC wires, irradiation cross-linked wires, and various customized wires and wire harness processing.

Packing & Delivery: