OEM H01N2-D/E 1000V Industrial Wiring Cable

OEM H01N2-D/E 1000V Temperature Resistant Industrial Wiring Cable

1.Application and Description

Automotive industry: For connection between welding robots and welding equipment in the automotive manufacturing process.

Shipbuilding: For welding operations in shipbuilding, especially in harsh marine environments.

Conveyor systems: As connection lines for welding tools and equipment in various conveyor and assembly lines.

Welding robots: As connection lines between robots and welding power sources in automated welding processes.

Battery storage systems: As battery cables or connection lines for battery storage systems, suitable for mobile and portable electrical devices.

The H01N2-D/E cable is ideal for powering portable electrical devices and equipment due to its combination of ruggedness and flexibility, especially for mobile installations under harsh conditions, such as automotive and shipbuilding, conveyors and assembly lines.

2. Cable Construction

Extra fine bare copper strands

Stranding to BS 6360 Class 5/6, IEC 60228 Class 5/6

Synthetic or paper separator over core

Chlorosulphonated Polyethylene (C.S.P.), HOFR (Heat and Oil Resistant and Flame Retardant) to BS7655 , black/ orange

3. Core Identification

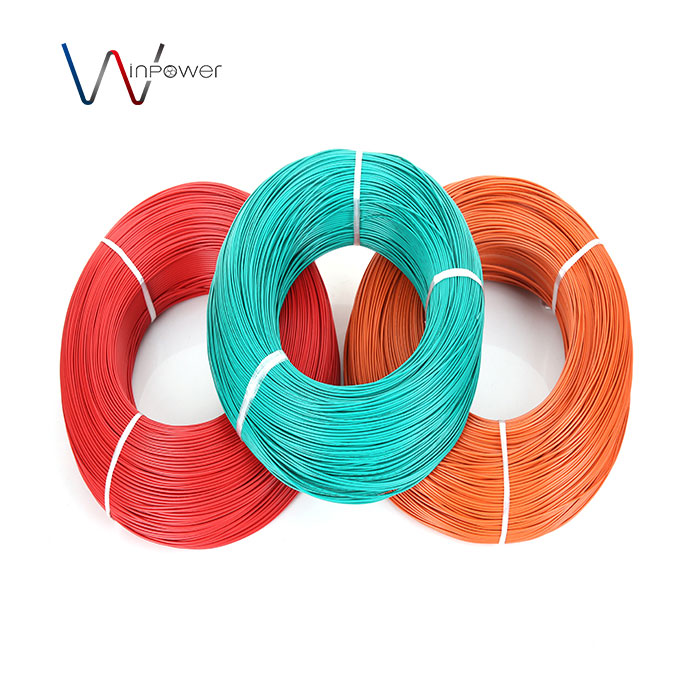

Blue (Blue), Grey (Grey), Green/Yellow (Green/Yellow), Brown (Brown), Special colours to order

4. Technical Characteristics

Working voltage:100/100 volts

Test voltage:1000 volts

Minimum bending radius:12.0xOverall diameter (H01N2-D)

10xOverall diameter (H01N2-E)

Flexing Temperature:-25 oC to +80 oC

Fixed Temperature:-40 oC to +80 oC

Flame retardant:IEC 60332.1CS

5. Cable Parameter

H01N2-D (standard flexibility)

|

AWG (No of Strands/Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area |

Nominal Thickness of Insulation |

Nominal Overall Diameter |

Nominal Copper Weight |

Nominal Weight |

|

#xmm^2 |

mm |

mm |

kg/km |

kg/km |

|

|

8(320/32) |

1×10 |

2 |

7.7-9.7 |

96 |

135 |

|

6(512/32) |

1×16 |

2 |

8.8-11.0 |

154 |

205 |

|

4(800/32) |

1×25 |

2 |

10.1-12.7 |

240 |

302 |

|

2(1120/32) |

1×35 |

2 |

11.4-14.2 |

336 |

420 |

|

1(1600/32) |

1×50 |

2.2 |

13.2-16.5 |

480 |

586 |

|

2/0(2240/32) |

1×70 |

2.4 |

15.3-19.2 |

672 |

798 |

|

3/0(3024/32) |

1×95 |

2.6 |

17.1-21.4 |

912 |

1015 |

|

4/0(614/24) |

1×120 |

2.8 |

19.2-24 |

1152 |

1310 |

|

300MCM(765/24) |

1×150 |

3 |

21.2-26.4 |

1440 |

1620 |

|

350MCM(944/24) |

1×185 |

3.2 |

23.1-28.9 |

1776 |

1916 |

|

500MCM (1225/24) |

1×240 |

3.4 |

25-29.5 |

2304 |

2540 |

H01N2-E(high flexibility)

|

AWG (No of Strands/Strand Diameter) |

No. of Cores x Nominal Cross Sectional Area |

Nominal Thickness of Insulation |

Nominal Overall Diameter |

Nominal Copper Weight |

Nominal Weight |

|

#xmm^2 |

mm |

mm |

kg/km |

kg/km |

|

|

8(566/35) |

1×10 |

1.2 |

6.2-7.8 |

96 |

119 |

|

6(903/35) |

1×16 |

1.2 |

7.3-9.1 |

154 |

181 |

|

4(1407/35) |

1×25 |

1.2 |

8.6-10.8 |

240 |

270 |

|

2(1974/35) |

1×35 |

1.2 |

9.8-12.3 |

336 |

363 |

|

1(2830/35) |

1×50 |

1.5 |

11.9-14.8 |

480 |

528 |

|

2/0(3952/35) |

1×70 |

1.8 |

13.6-17.0 |

672 |

716 |

|

3/0(5370/35) |

1×95 |

1.8 |

15.6-19.5 |

912 |

1012 |

|

4/0(3819/32) |

1×120 |

1.8 |

17.2-21.6 |

1152 |

1190 |

|

300MCM (4788/32) |

1×150 |

1.8 |

18.8-23.5 |

1440 |

1305 |

|

500MCM (5852/32) |

1×185 |

1.8 |

20.4-25.5 |

1776 |

1511 |

6. Features

H01N2-D/E power cable, also known as German standard welding machine cable or NSKFFÖU wire, is a cable specially designed for electric welding machines and welding applications. Its main specifications and features are as follows:

Application range: Suitable for connection between electric welding generators and handheld welding rods and workpieces. Widely used in automobile manufacturing, shipbuilding, transportation systems, machine tool machinery, welding robots and other fields.

Environmental adaptability: Even under the influence of ozone, light, oxidation, protective gas, oil and petroleum, H01N2-D/E cable can still maintain its high flexibility.

Corrosion resistance: It has excellent corrosion resistance and can resist oil, strong acid, strong alkali, strong oxidant, etc.

Conductor material: It adopts bare copper stranded wire or tinned copper stranded wire, which meets the DIN VDE 0295 Class 6 standard and refers to IEC 60228 Class 6.

Insulation and sheath: The core wire insulation and outer sheath adopt EM5 type material or EI7 type material, which provides flame retardant and oil resistant properties.

Sheath color: usually black RAL9005.

Temperature range: suitable for temperature range from -30 degrees Celsius to 95 degrees Celsius, ensuring stable operation in various climate conditions.

Structure: single core, very fine multi-core copper conductor with rubber outer sheath, providing high flexibility and durability.

Safety standards: in line with international certification standards such as CCC, CE, CB, BS, SAA, SGS, etc., to ensure safe use.